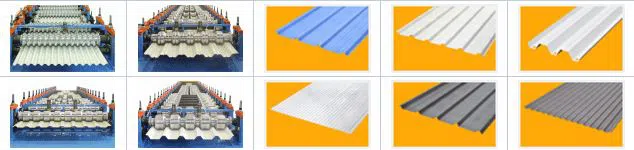

Roofing Ceiling Roll Forming Machine

we have supplied hundreds roofing machines to five continents. Yunsing not just offer machine, we focus on support client customize new profile and also improve current products. Base on stable and durable performance, Yunsing knows well on various Roofing profile in different markets. Maximize cover width, Logo embossing, Anti-capillary grooves, we also offer customized product for client to supply their innovative idea to market. serious including the most demanded products in worldwide markets, from 2ft to 4ft width available for both Coated Coil (PPGI/PPGL) and Galvanized Coil (GI/GL).

Description

Fully Automatic High speed Roofing ceiling roll forming machine base is available for Quick Change platform type, multi-profile purposes. Roofing ceiling roll forming machine are lighter than concrete or clay tile roofs and more durable than asphalt tile roofs. The metal roof panel is convenient for construction workers to perform on-site construction, which can save time. Metal roof tiles can be provided in different styles and designed to look at what customers want. Compared with other materials, the metal roofing system is cheaper. Roof tiles can be made to resemble other roofing materials, such as wood sway and asphalt shingles and slate.

Production Speed: 25/ 50/ 75 M/min. Product Length: 2.0 ~ 12M.

Raw Material: Pre-Painted Steel sheet G300 ~ 550. Plate Thickness: 0.3 ~ 0.6mm.

Automatic motorized cutting machine.(no hydraulic / pneumatic required).

Automatic piling device. Quantity / Batch automatic production mode available. With unloading chain for reducing the suspension time of different orders.

Machine Progress:

Decoiler → (Option: Pre Cut) → Rollforming → Motorized Cut-off → Conveyor → Double Sided Stacking device → Unloading Device