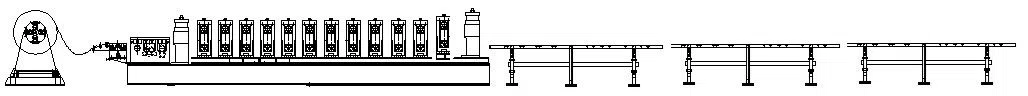

Ceiling Keel Stud Roll Forming Machine

Ceiling Keel Stud Roll Forming Machine has high safety performance, and has outstanding advantages such as corrosion resistance and long service life.

Description

Product Introduction Ceiling Keel Stud Roll Forming Machine has high safety performance, and has outstanding advantages such as corrosion resistance and long service life. The metal insulation layer currently used in some domestic nuclear power plant main equipment depends on advanced materials. The successful development of this product is a major progress in the nuclear power plant and equipment key technology autonomy and product localization. It can be used in aviation, defense and petrochemical industry. This Ceiling Keel Stud Roll Forming Machine adopts continuous production technology. The device integrates advanced digital control technology and hydraulic integration. It is made of high quality stainless steel, which has good strength and excellent resistance to corrosion and rust. In addition, our Ceiling Keel Stud Roll Forming Machine features advanced design concept, reasonable molding process, strong versatility, high strength, high performance and stable cold bending forming. It is also durable, can give a long service life with stable working performance. If you have any questions, please feel free to contact with us! TECHNICAL DESCRIPTION: Machine name: Ceiling keel stud roll forming machine Profile drawing: According with final client requirement Main Components: (1) Decoiler — 1 set (decoiler capacity is 3 tons) (7) Final product output rack — 1set (normally the length is 6 meters) (8) Spare part — 1 set (for one-year warranty time) How do we control quality? a) Pay attention to adaptation for manufacture process b) Approval report for shipment c) Third party inspection is accepted d)Keeping quality guarantee for a long times, up to two years. e) Guaranteeing quality inspection of each product before assembly and packing. f) Comply with ISO 9001