Rolls Leveler Machine

Suitable material width: 100~500mm Suitable material thickness: 3.0mm Yield strength of material sheet: max 1500Mpa Leveler rolls length: 600mm

Description

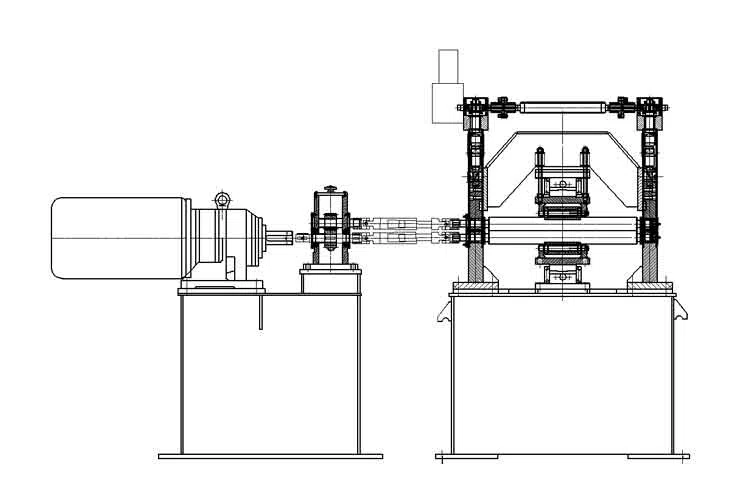

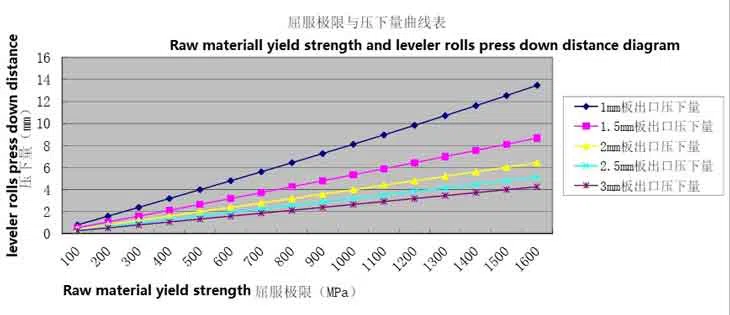

Suitable material width: 100~500mm Suitable material thickness: 3.0mm Yield strength of material sheet: max 1500Mpa Leveler rolls length: 600mm Planeness after the leveling process: 3mm/m Straightness after the leveling process: 1mm/m Leveler rolls diameter: ¢100mm (11 pieces) Leveler rolls material: 9Cr2Mo (HRC60~65) Pinch rolls diameter: ¢150mm Pinch rolls material: 40Cr (HRC48~55) Leveler working speed: 0~25m/min Support rolls list: 1 Support rolls material: GCr15 (HRC53~56) Leveler motor power: 90Kw Main components of leveler are base plate, rolls, lifting device, transmission part and etc. Leveler rolls are arranged in parallel. Down layer is fixed, up layer can be adjusted according to actual requirements. Up and down leveler rolls are all has support rolls. These support rolls installation location is lower than leveler rolls. These support rolls support the enough support power for the leveler rolls, in order to make leveler rolls have big enough power to level the raw material sheet. These support rolls also can keep the leveler rolls not to be arch on working process and great part leveling pressure will be borne by support rolls. Up layer leveler rolls can be adjusted by motor, decelerator, worm and gear, etc. the adjustment is easy and convenient. Up layer rolls are installed on moving beam, it is convenient to adjust the leveling angle. Up leveling rolls can be quick reset in time. According with the different leveling angle, the different thickness material sheet can get the good leveling quality. Leveler also includes one pair pinch rolls, up and down pinch roll are all power roll. They are driven by gearbox and transmission shaft. Their working speed is same as leveler rolls in anytime. Hydraulic power drives the pinch rolls press down action. Leveler is driven by DC motor, up and down leveler rolls are all power model, main aim is to avoid the material sheet to be sliding. It is suitable for the high precision cut-to-length requirements. The lubrication method is centralized grease lubrication. Machine outer form reference picture: Machine structure reference show: Special note: the leveler rolls lift’s up/down adjustment method is phased adjustment, different thickness coil will use different leveler rolls gap. Seller will supply the “Leveling rolls adjustment diagram”. It can be seen as following picture show: