Sheet Metal Roll Forming Machines

(1) Machine name: metal sheet roll forming machine (2) Profile drawing: According with final client requirement

Description

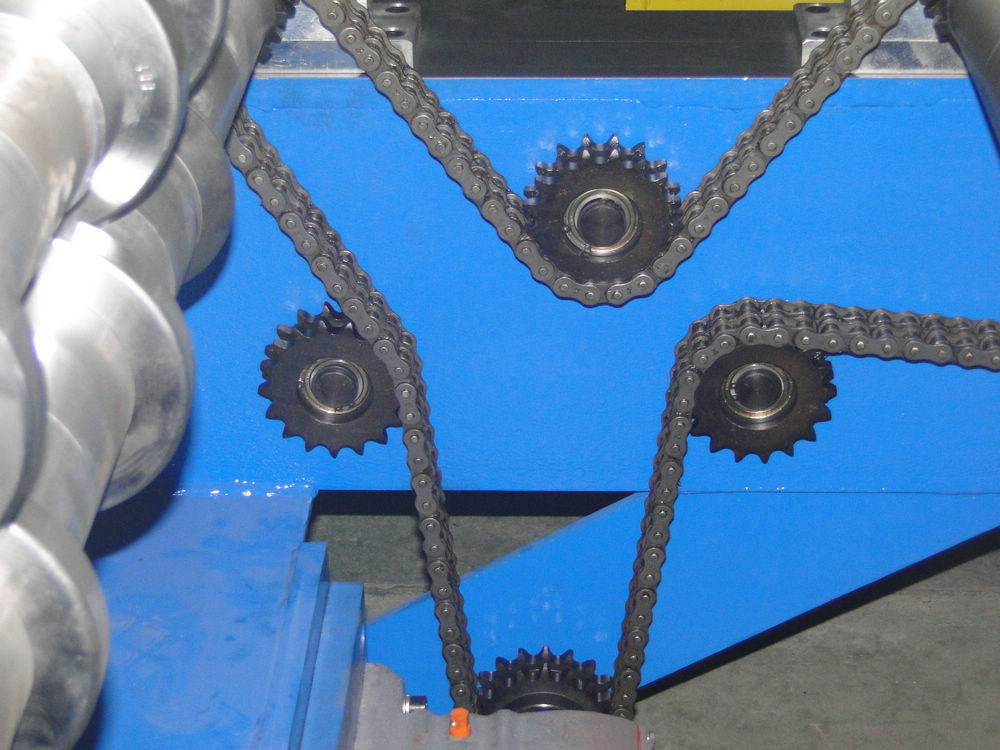

TECHNICAL DESCRIPTION: (1) Machine name: metal sheet roll forming machine (2) Profile drawing: According with final client requirement Ø Plate raw material parameters: (1) Raw material coil sheet Width: according with final test data (2) Raw material coil sheet thickness: 0.3~0.5mm/0.4~0.8mm/0.8~1.2mm (3) Raw material kind: PPGI/PPGL/GI/CR Steel (4) Raw material yield strength: 235Mpa 235~350Mpa 350~550Mpa (5) Raw material steel coil inner diameter: ¢508mm/¢610mm (6) Raw material steel coil outer diameter: ≤¢1300mm (7) Raw material steel coil max weight: 5 Tons Ø Main working data of the corrugated roof sheet making machine: (1) Actual working speed: 10~15m/min (common mode) 15~25m/min (fast speed mode) (2) Each piece final products length tolerance: ±2.0mm (common control system) ±1.0mm (precise control system) (3) Roll forming line power source: 380V/50Hz/3 Phase 440V/60Hz/3 Phase Ø Corrugated roof sheet making machine working process: Decoiler→feeding guide device→roll former→cutter→final products output rack Simple line lay-out drawing (just like reference): Ø Main components of the corrugated roof sheet making machine: (1) Decoiler–1 set (decoiler capacity is 5 tons) (2) Feeding gudie device– 1 set (3) Roll former– 1 set (4) Hydraulic Cutter– 1 set (5) Hydraulic system– 1set (6) PLC control system – 1 set (PLC+HMI operation style) (7) Final product output rack—1set (normally the length is 6 meters) (8) Spare part– 1 set (for one-year warranty time)