Metal Roofing Sheet Making Machine

Roll forming, also spelled roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.

Description

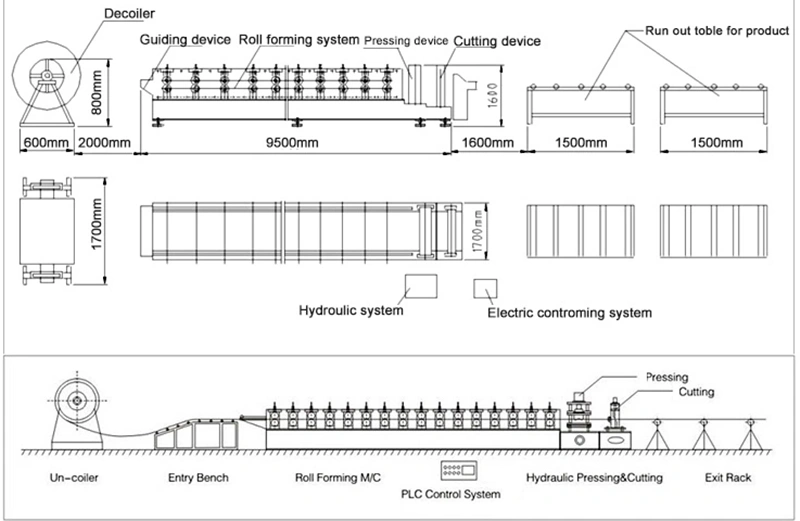

Product Introduction This Metal Roofing Sheet Making Machine adopts continuous production technology. The device integrates advanced digital control technology and hydraulic integration. It is made of high quality stainless steel, which has good strength and excellent resistance to corrosion and rust. In addition, our Metal Roofing Sheet Making Machine features advanced design concept, reasonable molding process, strong versatility, high strength, high performance and stable cold bending forming. It is also durable, can give a long service life with stable working performance. If you have any questions, please feel free to contact with us! Parameters: Main Working Data: Working Process: Decoiler → feeding guide device → roll former → cutter → final products output rack Simple line lay-out drawing (just like reference): Our service: Professional sales staff reply your questions with in 24 hours in fluent English. Most of products are in stock. Because the clustering of supply chain and our high production efficiency, even the special request item have better lead time than any other place. Use high quality material, have better production management. We provide you the technical consultation to have suitable products and methods, that make your life easy.

Type

Tile Forming Machine

Tile Type

Colored Steel

Use

Roof,Wall

Production Capacity

12 m/min

Voltage

220/380/440V

Dimension(L*W*H)

8000*1650*1500mm

Weight

5T

Certification

CE/ISO9001

Warranty

1 YEAR

Rolling thinckness

0.3-0.8mm

Feeding width

1220mm, 915mm, 900mm, 1200mm, 1000mm, 1250mm

Color

Client’s Request

Control system

Taiwan Delta

Thickness

0.3–0.8mm

Effective width

760-1260mm

Actual working speed

10~15m/min (common mode)

Each piece final products length tolerance

±2.0mm (common control system)

Roll forming line power source

380V/50Hz/3 Phase