Roller Shutter Door Roll Forming Line

(1)Suitable Coil Thickness: 1.2mm (2)Raw material feeding width: according with actual test parameter (3) Suitable Raw Materials: galvanized steel/cold rolled steel (4) Raw material yield strength: 235~300Mpa

Description

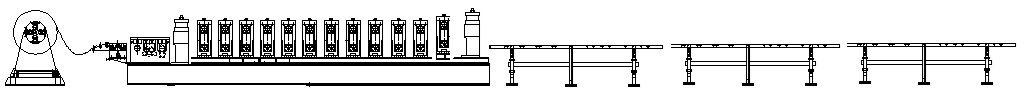

technical scheme name of goods: Roller shutter door plate roll forming line PROFILE DRAWING: Note: about the profile drawing, it still has unmarked dimension part. The quotation file profile drawing is only reference drawing. Before the order is singed, the detailed profile drawing will be signed by both parties. Ø MATERIAL: (1) Suitable Coil Thickness: 1.2mm (2) Raw material feeding width: according with actual test parameter (3) Suitable Raw Materials: galvanized steel/cold rolled steel (4) Raw material yield strength: 235~300Mpa (5) suitable steel coil inner diameter: ¢508mm (6) suitable steel coil outer diameter: ≤¢1200mm (7) Suitable steel coil max weight: 2 Tons Ø MAIN TECHNIQUE DATA OF LINE: (1) Line working speed: 15~20m/min (without cut time) (2) Each piece final products length tolerance: ±1.5mm (3) Roll forming line power source: 380V/50Hz/3 Phase (4) Suitable temperature of roll forming line: -10℃~35℃ (5) Complete line power: 11.5Kw (6) Main color of roll forming line: from left to right (when operator faces the control panel)(7) Roll forming line working direction: Ø ROLL FORMING LINE WORKING PROCESS: Decoiler-main roll former (includes leveler and pre-punch device) – hydraulic cutter-final plate output rack Simple line lay-out drawing (just like reference): Ø MACHINE COMPONENTS: Ø LINE TECHNICAL SPECIFICATION OF EACH PART (1) Manual decoiler: This decoiler is no power model; when the steel coil is loading on decoiler shaft, operator needs to expand steel coil inside part manually. The decoiler is single shaft mode, max loading capacity: 2000kg Suitable steel coil inner diameter: ¢508mm Suitable steel coil outer diameter: ¢1200mm In order to make decoiler can be stopped on the working condition when some urgent thing is happened, decoiler includes the simple brake device. It is mainly used to make decoiler shaft to be stopped moving in time. When the line is on working condition, decoiler shaft will move passively and decoiler shaft moving power is driven by main roll former parts. The machine outer form reference picture: (2) Pre-punch device: Pre-punch device is used to punch the group hole (1 ground hole includes 4 square holes and 1 circle hole). It is installed between the feeding guide and first roll forming stand. Feeding guide is manual model, the guide width can be adjusted manually. Main aim is to make feeding sheet can be get into pre-punch part on correct direction. Pre-punch is driven by hydraulic cylinder. It will punch the group hole (5 holes) at same time. The punch hole distance can be adjusted on control system according with actual requirement. Pre-punch device also includes 1 complete set punch die, these punch dies are used to punch 5 holes. Punch die material: Cr12MoV (HRC58~62) (3) Main roll former: Main roll former part is single forming stand model, the base plate is weld steel structure style. Main roll former forming stand number: 12 All the forming stand power part is on the bottom forming shaft. The transmission part is on the bottom shafts part. The transmission system includes main motor (servo motor), decelerator, toothless chain, gear, chain wheel and etc Toothless chain reference picture: The forming roller is designed by professional software, and complete rollers’ dimension is precise, all roller surface is polishing treatment. Forming roller material: Cr12 (HRC58~62) (The physical characteristics is almost same as America D2) Forming shaft material: 40Cr (HRC45, hardening and tempering) Forming shaft dimension: ¢60mm Main roll former working speed: 15~20m/min Main motor power: 7.5Kw Motor kind: servo motor Motor brand: Yasukawa (Japanese product) Main roll former outer form reference picture: (4) Hydraulic Cutter The cutter model is stop to cut; when cutter is working, roll forming line needs to stop; when cut action is finished, roll forming line will work again. The cutter is driven by hydraulic cylinder. Theree is one waste piece after cut actions. This cut model can make profile arch part to be well after the cut action. Cutter blade material: Cr12MoV (HRC58~62) Cut length tolerance: ±1.5mm. The cutter can be cut the final products on confirmed length, and the length is automatically fixed by control system. The encoder will be installed in the front of cutter, it will send the signal to PLC, PLC also will pick-up information from servo motor. By this way, servo motor and encoder will be worked under “Closed loop control”. (5) Hydraulic system: It supplies the power for the hydraulic puncher and cutter. This system is specially design for roll forming line, it will make pre-punch and cutter working speed to be fast and working condition to be stable. Hydraulic system mainly includes oil tank, oil pump, filter, accumulator, hydraulic electromagnetic valve, press meter and motor, etc. in order to make system to be work well when roll forming line on long times working condition, system matches with fan cooling system, it will keep system hydraulic oil temperature on suitable degree. Electromagnetic valve brand: ATOS Hydraulic motor power: 4Kw System outer form reference picture: (6) Electrical control system: This system uses PLC to control all working actions. Production quantity and each piece length will be automatically measured; human and machine interface, operator can use touch screen to input and cancel the working data. The control panel has English operation interface, it is convenient to operator to input and cancel working date and make roll forming line operation. Main electrical accessories list: PLC: Schneider (French product) Touch screen: WEINVIEW (China Taiwan product) Transducer: Schneider (French product) Low-voltage apparatus: Schneider (French product) Encoder: Schneider (French product) (7) Final plate output rack: The rack is no power model, totally it has three parts, each part length is 2 meters, total length is 6 meters. This rack can be adjusted up and down, main aim is satisfy the workshop ground level condition, and operator can adjusts it easily. Final plate rack is used to collect the final product sheets and final product sheets are convenient to be stacked by workers. This rack can be disassembled easily, in order to satisfy different working condition requirements. Plate rack outer form reference picture:

No.

Component name

Unit

Quantity

Note

1

Manual decoiler

Set

1

2 tons capacity

2

Pre-punch device

Set

1

Hydraulic power model

3

Main roll former

Set

1

Single forming stand model

4

Hydraulic cutter

Set

1

Back cutter, stop to cut model

5

Hydraulic system

Set

1

Includes accumulator

6

Electrical control system

Set

1

PLC control model

7

Final plate output rack

Set

1

3 pieces, total length is 6 meters