Economical Rock Wool Sandwich Panel Production Line

Economical rock wool sandwich panel production line is a special production equipment for new building materials. Its main function is to compound color steel on thicker and lighter core material EPS board or rock wool board, and to compound it under continuous operation.

Description

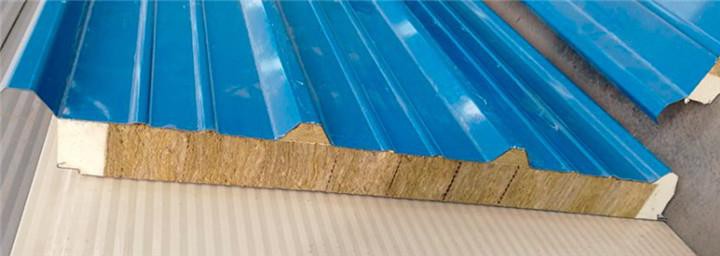

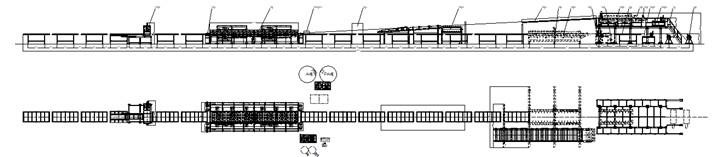

PROFILE DRAWING: 1. Roofing Panel: 2. Wall Panel: General Introduction: Economical rock wool sandwich panel production line is a special production equipment for new building materials. Its main function is to compound color steel on thicker and lighter core material EPS board or rock wool board, and to compound it under continuous operation. The board is accurately cut to realize the mechanization and automation of the entire production process. The production line of rock wool sandwich panel developed by our company is based on colored coated steel plate, self-extinguishing polystyrene, polyurethane, glass wool, and rock wool as core material, and uses thermosetting glue in continuous molding machine. Ultra-light construction board made of heat and pressure. Can produce EPS flat board, EPS tongue and groove board, EPS corrugated board, rock wool flat board, rock wool tongue and groove board, rock wool corrugated board and other board types. The core materials that can be used are: foam, expandable polystyrene foam, rock wool, polyurethane and suitable core materials. This economical rock wool sandwich panel production Line is used to produce common rock wool sandwich panel. Both surface of panel is steel sheet, the core material is rock wool, the side cover part is PU. This line can produce one roofing panel and one wall panel. If customers want to produce the other kind of sandwich panel, the line can produce two kinds roofing panel and one kind wall panel. In addition, our Economical Rock Wool Sandwich Panel Production Line features advanced design concept, reasonable molding process, strong versatility, high strength, high performance and stable cold bending forming. It is also durable, can give a long service life with stable working performance. If you have any questions, please feel free to contact with us! Actual panel reference picture: Main Technical Parameters: Working Process Show: Components:

Suitable width of sandwich panel

1000mm

Suitable length of panel

3000~15000mm

Suitable panel thickness

50~100mm

Suitable steel sheet thickness

0.4~0.6mm

Suitable steel sheet kind

color steel sheet

Steel sheet yield strength

235Mpa

Roll forming line speed

3~8m/min (actual working speed is decided by foaming material technics)

Double belt device length

10 meters

Total power of roll forming line

90Kw

Roll forming line dimension

80m×10m×3m (L-W-H)

Manual decoiler

2 sets

Motor power pre-cut

2 sets

Filming device

2 sets

Roll former

2 sets

Rock wool transfer device

1 set

Gluing device

1 set

2 components’ PU foaming device

1 set (for sandwich panel side part cover)

Belt machine

1 set

Roofing panel side block

1 set

Wall panel side block

1 set

Beltsaw cutter

1 set (not includes Soundproof room)

Control system

1 set

Steel structure flat

1 set

No power final panel output rack

1 set

Send Inquiry

You Might Also Like

- * no