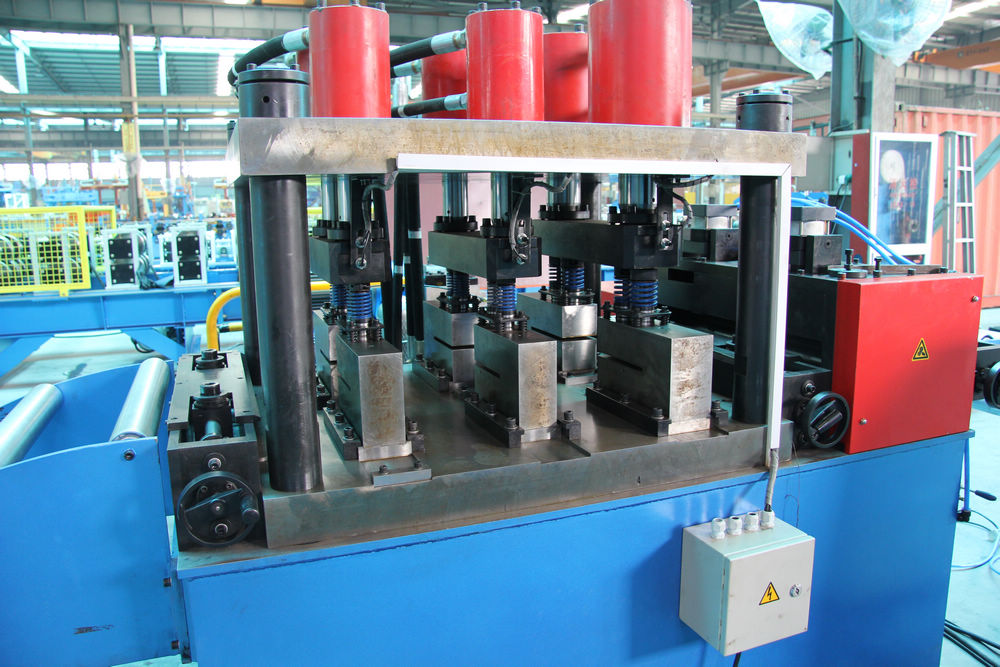

Multi-Station Hydraulic Puncher

This multi-station hydraulic puncher is multi-station mode, it includes few working units. By this kind of structure, puncher can finished few punch holes on same device.

Description

Multi-station hydraulic puncher is easy to operate, safe and reliable. The hydraulic hole opener can be used for the installation and maintenance of wire and pipe, indicator lights, instrument switches and other holes in the metallurgy, petroleum, chemical, electronics, electrical appliances, shipbuilding, machinery and other industries. It is more suitable for the formed instrument panel bottom plate and switch box branch. The wall of the electrical box is used for opening. PUNCH DRAWING: According with final client requirement. This multi-station hydraulic puncher is multi-station mode, it includes few working units. By this kind of structure, puncher can finished few punch holes on same device. Puncher is hydraulic power mode, the structure is “Three-beam and four-column structure” style. Puncher includes few working groups (according with actual punching and notching requirement). All the required holes and notch parts can be finished by this puncher. By this kind of puncher, if the neighbor holes’ horizontal distance or vertical distance is changed, operator can make adjustment for the punch die, in order to satisfy punch holes requirement. On the horizontal direction, the distance can be set on control system, operator needs not to make any adjustment on the punchers’ mechanical part; on the vertical direction, the distance has limited range, it cannot be adjusted freely. MATERIAL SHEET PARAMETERS: (1) Suitable Coil Thickness: 0.4~0.8mm/ 0.8~1.2mm/ 1.2~2.0mm/ 2.0~4.0mm/ 4.0~6.0mm (2) Raw material sheet kind: PPGI/ PPGL/ GI/ CR STEEL/ HR STEEL (3) Raw material yield strength: 235~550Mpa/ 550~750Mpa MAIN TECHNIQUE DATA: (1) Max working speed: 35m/min (2) Machine power source: 380V/50Hz/3 Phase (3) Suitable temperature of roll forming line: -10℃~35℃ (4) Complete line power: according with final punch hole and notch part drawings condition (5) Main color of machine: Main base plate RAL5015 RAL5015 (6) Machine working direction: from left to right (when operator faces the control switch) ROLL FORMING LINE WORKING PROCESS: Raw material sheet servo feeding → punching → punch sheet output MACHINE COMPONENTS: (1) Machine base plate (2) Servo feeder (3) Puncher frame (4) Punch die (few working units) (5) Hydraulic cylinder (6) Hydraulic system (7) PLC control system (8) Punch sheet output rack FAQ: 1.Are you Trading or Factory ? We are factory, Big quantity order is avaiable to us and the delivery time can be guaranteed 2.How Can I get contact with you about quotation? We usually quote within 24 hours after we get your inquiry online because of the time difference. For urgent condition, please call us (0086-18337386578) or email us so that we will regard your inquiry priority. 3.How can I get a sample to check your quality? After price confirmation, Photos and videos will be sent to you during the production process of the machine. 100% quality inspection. Product certificate can be provided.

Send Inquiry

You Might Also Like

- * no