Window Frame Roll Forming Machine

The window frame roll forming machine can produce various types of metal door and window frames, reinforcement, fire doors, etc. through the roll forming method. After passing the window frame roll forming machine, we can produce a very smooth and beautiful steel window frame without any scratches on the surface.

Description

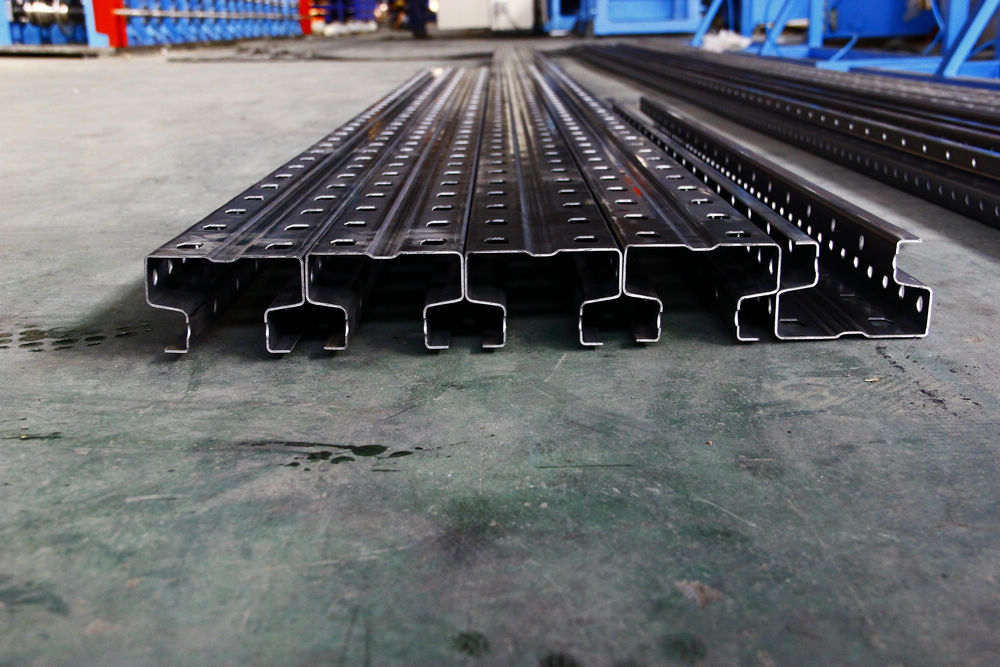

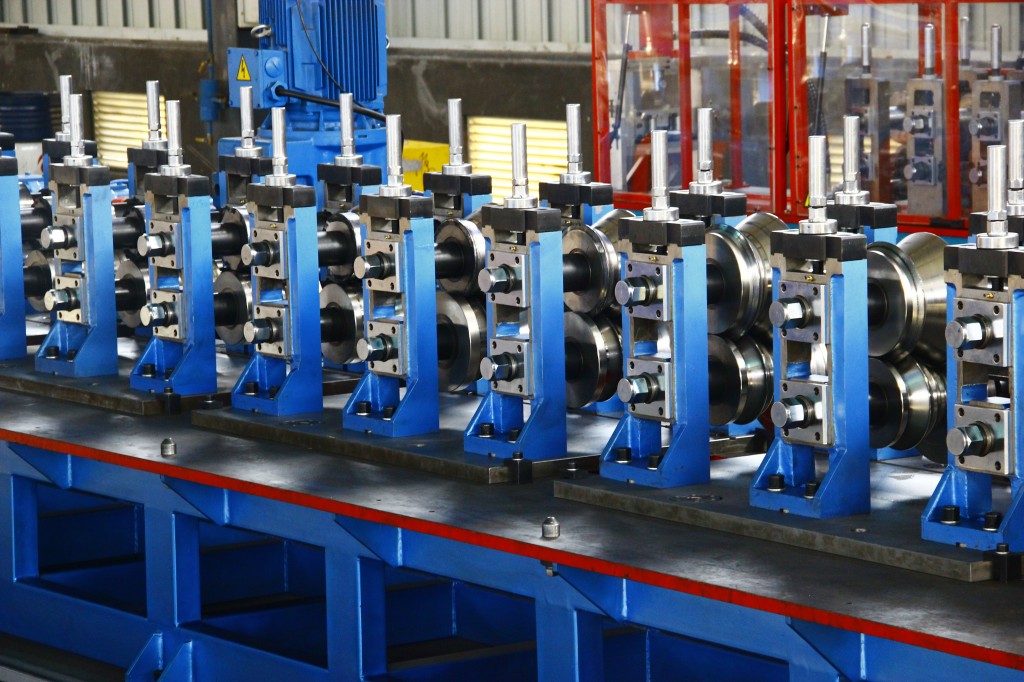

Product Introduction The window frame roll forming machine can produce various types of metal door and window frames, reinforcement, fire doors, etc. through the roll forming method. After passing the window frame roll forming machine, we can produce a very smooth and beautiful steel window frame without any scratches on the surface. The window frame and door frame roll forming machine is specially designed to produce strong and durable steel window frame or door frame. Our window frame roll forming machine consists of a hydraulic uncoiler with a breaking device, a straightening machine, a servo roll feeding machine, an online multi-station hydraulic punching device, a roll forming machine with tools, a hydraulic cutting machine, a beating table and automatic stacking device and other components. This window frame roll forming machine adopts continuous production technology. The device integrates advanced digital control technology and hydraulic integration. It is made of high quality stainless steel, which has good strength and excellent resistance to corrosion and rust. In addition, our window frame roll forming machine features advanced design concept, reasonable molding process, strong versatility, high strength, high performance and stable cold bending forming. It is also durable, can give a long service life with stable working performance. If you have any questions, please feel free to contact with us! Technical Parameters: Equipment List: Working Process De-coiling → Leveling → Guiding system → Puncher → Straitening → Roll forming → Straighter → Cut to length → Run out Table Profile Drawing According with different client requirements. We can make customized mode roll forming line. Machine Layout Description Of All Components: A) 5 Ton Dual-Head Hydraulic Decoiler 1. Function and components 5) Punch capacity Material: Cr12MoV, hardness HRC58-62 The punching speed is 70 times/min G) Roll Former Roll former uses independent structure, independent drive chain Shaft diameter: Ø60mm.Ø Roll material: Cr 12, quenching hardness HRC58-62. Surface polished.

NO

Item

Parameters

Remark

1

Suitable material

Type

Galvanized sheet

Thickness (mm)

0.8-1.2mm

Grade

235Mpa

Coil Width (mm)

227mm

2

Producing Speed (m/min)

Variable 18-25 m/min

Including cutting & punching time

3

Roll former Main Motor Power (KW)

11Kw

4

Hydraulic station power for punching and cutting (KW)

22Kw

5

Leveling motor power (KW)

3kw

6

Decoiler hydraulic power (KW)

2Kw

7

Servo feeding motor power (KW)

2.2 kw

8

Servo flying shear motor power

2.2 kw

9

Hydraulic cutting power (KW)

11kw

10

Total power

53kw 380V 50HZ 3phase

Power source according to client’s final confirmation

Structure

Decoiler type

Expanding type

Press Arm

Coil car

Hydraulic system

Electric control system

Dual head type

Motor/ passive

Hydraulic

No

No

Shared

Shared

Roll former stations: 22 main station

Roll forming station material QT470.Ø

Shaft is made of 40Cr, quenching hardness HRC45.

Roll former machine motor power: 11KW use SEW brand – German