Guard Rail Roll Forming Machine

Guard Rail Roll Forming Machine adopts reasonable design, suction box, forming and bottom sealing are automatically processed in one go.

Description

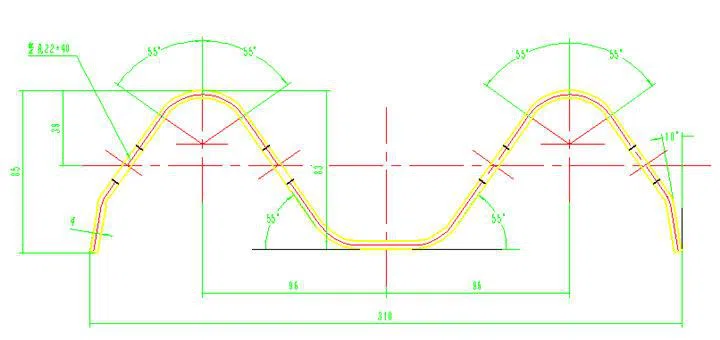

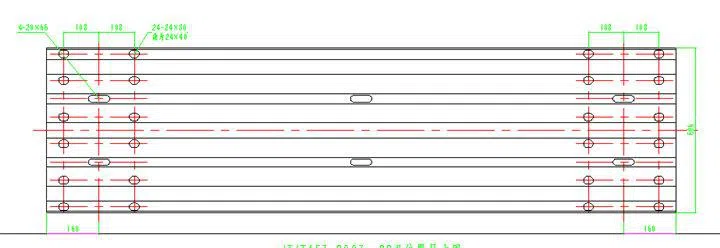

Product Introduction Guard Rail Roll Forming Machine adopts reasonable design, suction box, forming and bottom sealing are automatically processed in one go. The performance of the parts is precise and durable. There is no vibration in the operation process, and the operation life is stable and long. It makes the operation more convenient, and its control program is designed like a fool. Therefore, our Guard Rail Roll Forming Machine can be operated without professional training. Please let us know if you are interested! Profile Drawings: Note: when order is confirmed, both parts need to sign the profile drawing and punch hole drawing together. Main Components Decoiler 1 set (includes coil car) This deociler is single head model, motor drives decoiler shaft to open steel coil and hydraulic power make decoiler shaft expanding device to make steel coil to be fixed well on decoiler shaft. When complete line is on common working condition, decoiler is working automatically. In order to make decoiler operator to be safe, decoiler also includes pneumatic brake and press arm. It will protect operator among working process. In the front of main leveler part, one special Telescopic shovel head is installed on leveler base plate. When raw material will get into leveler part, this shovel will move up and guide raw material to get into leveler device smoothly. Max working speed: 30m/min Suitable steel coil thickness: max 4.0mm Motor power: ≈11Kw The decoiler and leveler device outer form reference picture Material loop 2 sets Material loop is used to make working speed to be matched for different necessary parts. Complete line totally includes 2 sets loop. One loop is between leveler and puncher, the last one is between puncher and main roll former. Within the loop channel, it includes few photoelectric switches. These switches are used to control raw material feeding location in each loop channel. 500T pressure machine 1 set This kind of pressure is special hydraulic puncher model, it includes complete punch die and different punch die is used to finished different holes’ punching action. Punch die will finish the punch hole and material sheet cut-to-length action completely. Main components of pressure puncher are base plate, punch die, punch frame, adjustable device and related assistant accessories, etc. The pressure puncher will includes 2 sets punch dies. They are used to finish 18 holes for 2 waves guard rail plate and 28 holes for 3 waves guard rail plate punch action requirement. The punch holes’ drawings as following show: Special strength hole puncher 1 set This kind of puncher is common punch model. It will includes 2 sets punch dies, main aim is to finish 2 and 3 wave guard rail plate strength hole punch action requirement. Machine outer form reference picture Main roll former 1 set Main roll former is single forming stand model, motor, decelerator, transmission shaft and gearbox drives roll former to form profile. Fast change cassette reference picture: All roll forming rollers are finished machining and polishing for roller surface. Roller material is Cr12 (HRC58~62), the physical character is similar as American D3 material. Main roll former outer form reference picture: Final products output rack This rack total length is 4 meters, it has two parts, each part length is 2 meters. Rack is easy to assemble, when complete line needs to have some location adjustment, operator can disassembly it soon.