High End Cut-To-Length Line

High End Cut-To-Length Line is used to cut flat rectangular blanks from the main coil. Provide a maximum width of 1250mm, a maximum thickness of 2.0mm and a speed of 20m/min.

Description

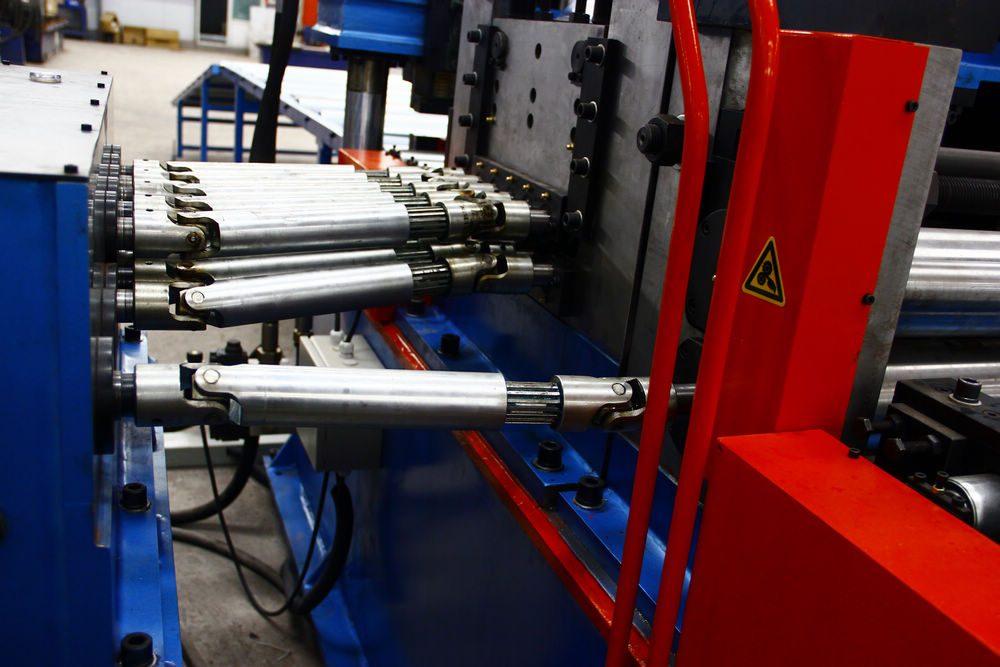

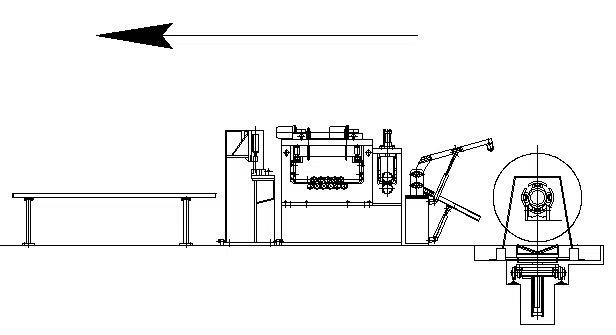

High End Cut-To-Length Line is used to cut flat rectangular blanks from the main coil. Provide a maximum width of 1250mm, a maximum thickness of 2.0mm and a speed of 20m/min. High End Cut-To-Length Line is completely controlled by computer, with functions of diagnosis, automatic coil feeding and quality control. Mainly suitable for carbon steel, stainless steel, painted steel, aluminum and other metal materials. MATERIAL: (1) Coil Width: max 1250mm (2) Suitable Coil Thickness: 0.5~2.0mm (3) Suitable Raw Materials: cold rolled steel/ hot rolled steel (yield strength: σs≤300Mpa) (4) suitable steel coil inner diameter: ¢508mm/ ¢610mm (5) max steel coil outer diameter: ¢1200mm (6) Suitable steel coil max weight: max 10Tons MAIN TECHNIQUE DATA OF LINE: (1) Line working speed: 20m/min (2) Each piece final products length tolerance: ≤±2mm (according to the basic length: 1000mm) (3) Final products length range: 1000~3000mm (4) Roll forming line power source: 380V/50Hz/3 Phase ROLL FORMING LINE WORKING PROCESS: Decoiler and decoiler car-leveler-material guide device-cutter-final products rack Simple line lay-out drawing (just like reference): MACHINE COMPONENTS: Hydralic decoiler with decoiler car ,Material guide device,Leveler machine,Straighter device,Hydraulic cutter,PLC control system,Hydraulic system,Final products rack — each 1 set LINE TECHNICAL SPECIFICATION OF EACH PART: (1) Hydraulic Decoiler With Decoiler Car: This decoiler is assistant support model, it includes a decoiler car. Motor power drives decoiler shaft opens steel coil, and hydraulic power expands steel coil inner diameter. The decoiler is assistant support model, max loading capacity: 10000kg Suitable steel coil inner-diameter: ¢508mm/¢610mm Max outer diameter: ¢1200mm Decoiler shaft expanding range: 50mm (¢465mm~¢515mm) When the high end cut-to-length line is working, the decoiler is moving following the complete line working actions. Also the decoiler includes brake device, when the line has urgent trouble, the decoiler can be stop in time. The decoiler car is driven by motor, and max loading capacity is 10 tons. Decoiler car move speed is 3m/min, and it can move forwardly and back on horizontal guide rail. Note: When the decoiler and decoiler are installed well, the decoiler car is under ground. (Please see reference lay-out drawing at the second page.) (2) Material Guide Device: The device includes press arm and material guide table. Press arm has power roller to press well the raw material; and material guide table will support the coil head and end part when those parts are sent leveler machine. Press arm and material guide table are all driven by hydraulic power. Machine outer form reference (3) Leveler Machine: Main parameters of leveler machine: Pinch roller number: 1 pair Leveler roller number: 11 pieces Leveler roller material: 60CrMoV Main roll former working speed: about 20~25m/min Main motor power: about 22Kw About the leveler structure, 5 leveler rollers are on up layer, and 6 leveler rollers are on down layer; up and down layer leveler roller are all have 3 lists support roller. The leveler roller space can be adjusted, and leveler obliquity can be adjusted. The leveler driver system includes motor, decelerator, wheel box and coupling, etc. Suitable power voltage: 380V/50Hz, 3 phase (4) Straighter Device: 2 groups’ vertical straighter rollers are located in the front and back of the leveler All rollers are installed on separated slider, and use manual power to adjust slider on forward and back direction. In order to satisfy different width material requirements. (5) Hydraulic Cutter: Non-load continuously working action number: ≤20 times Cut degree: 1.5° Hydraulic power drives the cutter, when the cutter blade is moving on cutter frame, one twist spindle will force the hydraulic cylinder to be in-phase by 2 pairs gear rack. Cutter blade space can be adjusted by working flat. On the entrance of the cutter, the support table has support roller, and the exit part of the cutter also has support roller, and those rollers will move following the cutter frame working action. (6) PLC Control System: This system uses Mitsubishi (or same level brand products) PLC to control all working actions. Production quantity and each piece length will be automatically measured; human and machine interface, the working data can be input and cancelled on control panel. It is convenient to control the complete line. The control panel has English operation interface, it is convenient to operator to input and cancel working date. All line has 3 working operation models; it is adjustable, manual and automatic. Different working operations will satisfy different working action requirements. Main electric accessory products shown: PLC: MITSUBISHI (or same quality brand products) Transducer: DELTA (China Taiwan) Coder: OMRON (7) Product Rack (UN-Powered): One part, total length is 3 meters. In order to collect the final product and final products is convenient to be stacked by workers. This rack can be disassembled easily, in order to satisfy different working condition requirements.

Machine outer form reference: