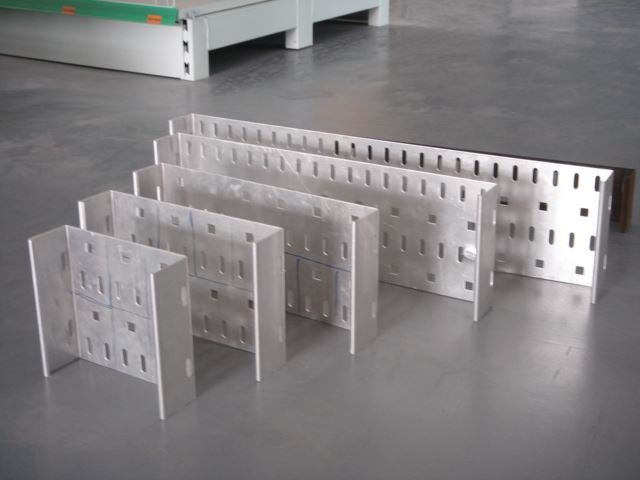

roduct Description

Cable tray roll forming line is currently in production for many bridge companies. Cable tray roll forming equipment can produce bridges of different specifications, the width can be adjusted according to the actual test index, and it has strong flexibility. The production speed is fast, the molding effect is good, the rolling has few scratches, and the cutting is without deformation. At the same time, the equipment is simple and can be produced normally by one person.

This Cable Tray Roll Forming Line adopts continuous production technology. The device integrates advanced digital control technology and hydraulic integration. It is equipped with electronic control and hydraulic equipment. In addition, our Cable Tray Roll Forming Line features advanced design concept, reasonable molding process, strong versatility, high strength, high performance and stable cold bending forming. It is also durable, can give a long service life with stable working performance. The application of this machine will bring you more convenience and economic benefits! Please let us know if you are interested!

SUITABLE MATERIAL

| Suitable Coil Thickness |

1.5~3.0mm |

| Raw material feeding width |

according to actual test parameter |

| Suitable Raw Materials |

galvanized steel/cold rolled steel |

| Raw material yield strength |

235~350Mpa |

| suitable steel coil inner diameter |

¢508mm |

| suitable steel coil outer diameter |

≤¢1300mm |

| Suitable steel coil max weight |

5 Tons |

MAIN TECHNIQUE DATA

| Line working speed |

10~15m/min |

| Each piece final products length tolerance |

±2.0mm |

| Roll forming line power source |

380V/50Hz/3 Phase |

| Suitable temperature of roll forming line |

-10℃~35℃ |

| Complete line power |

42Kw |

| Roll forming line working direction |

from left to right (when operator faces the control panel) |

ROLL FORMING LINE WORKING PROCESS:

Decoiler-leveler-servo feeder and mechanical press machine-roll former-hydraulic cutter-final plate output rack

Simple line lay-out drawing (just like reference):

MACHINE COMPONENTS:

| No. |

Component name |

Unit |

Quantity |

Note |

| 1 |

Decoiler |

Set |

1 |

5 tons capacity |

| 2 |

Leveler |

|

|

7 rolls mode |

| 2 |

Servo feeder and press machine |

Set |

1 |

Mechanical press machine |

| 3 |

Main roll former |

Set |

1 |

Gear box and transmission shaft drives |

| 4 |

Hydraulic cutter |

Set |

1 |

Back cutter, stop to cut model |

| 5 |

Hydraulic system |

Set |

1 |

Includes cooling fan |

| 6 |

Electrical control system |

Set |

1 |

PLC control model |

| 7 |

Final product output rack |

Set |

1 |

2 pieces, total length is 6 meters |