Roll Forming is an efficient, effective shaping that delivers tight tolerances on complex profiles.

Feb21,23

Roll Forming is an efficient, effective shaping that delivers tight tolerances on complex profiles.

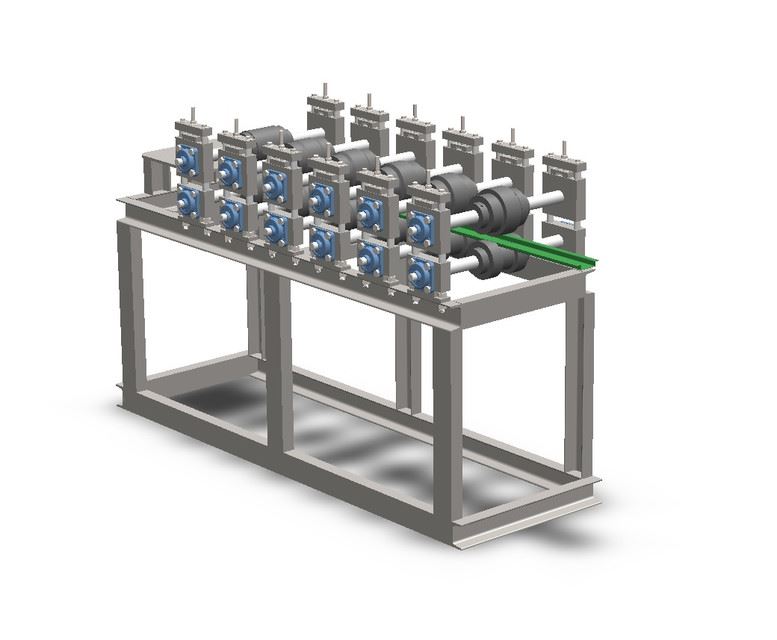

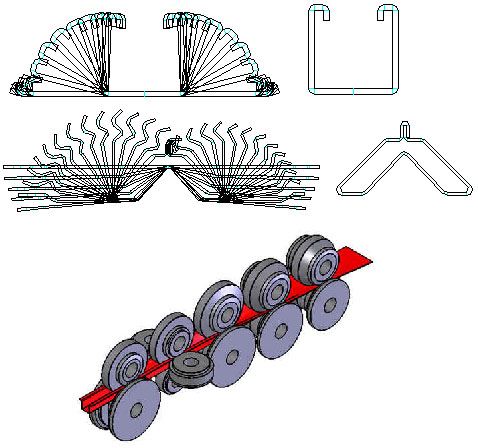

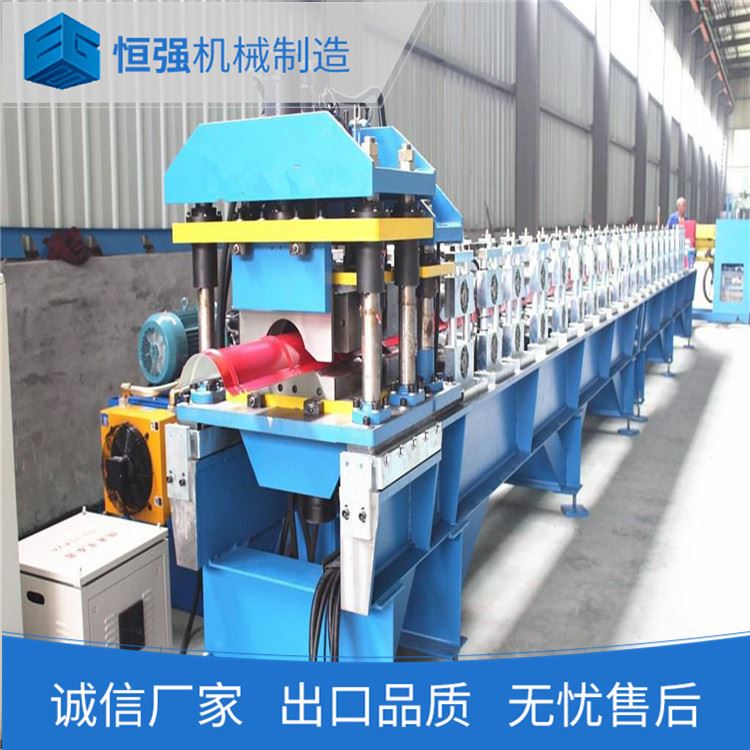

Roll forming is a reliable, proven approach to metal shaping that is ideal for modern applications. This process uses a continuous bending operation where long metal strips, typically coiled steel, are passed through consecutive sets of rolls at room temperature. Each set of rolls performs incremental parts of the bend to produce the desired cross-section profile. Unlike other metal shaping methods, the roll forming process is inherently flexible. Secondary processes can also be integrated into a single production line. Roll forming increases efficiency while reducing operational and capital costs by eliminating unnecessary handling and equipment.

Typical roll forming mills can accommodate material gauges ranging from .010″ up to 0. 250″ thick. The bend radius is largely determined by the ductility of the metal. However, 180-degree bends are commonly achieved with the right material. Roll forming easily accommodates the integration of secondary operations such as welding, punching and precision laser cutting to optimize production efficiency.