Roll Forming Basics and the Roll Forming Process

Feb21,23

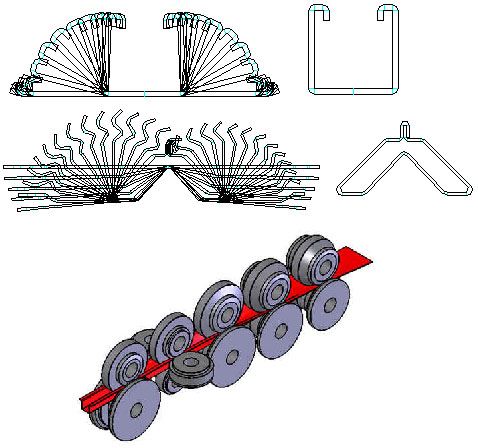

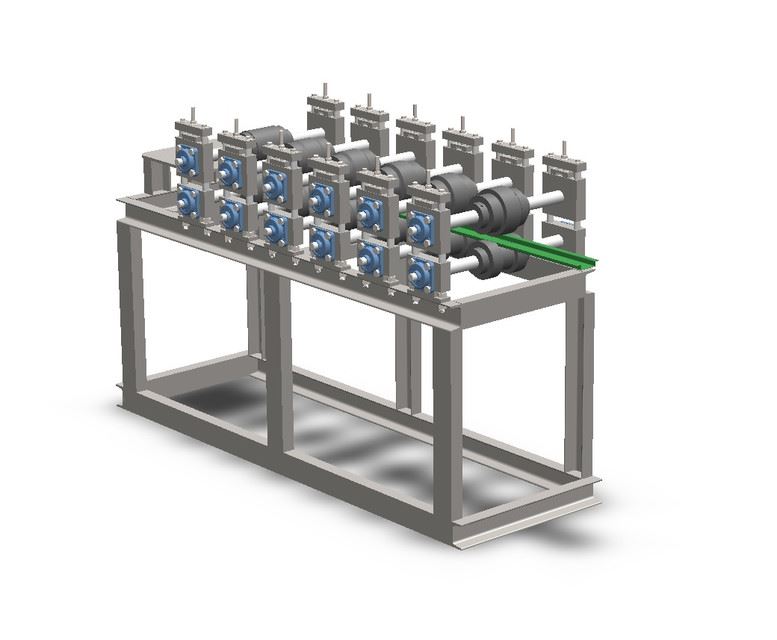

The basic roll forming machine has a line that can be separated into four major parts. The first part is the entry section, where the material is loaded. The material is usually inserted in sheet form or fed from a continuous coil. The next section, the station rollers, is where the actual roll forming takes place, where the stations are located, and where the metal shapes as it makes its way through the process. Station rollers not only shape the metal, but are the main driving force of the machine.

The next section of a basic roll forming machine is the cut off press, where the metal is cut to a pre-determined length. Due to the speed at which the machine works and the fact that it is a continuously working machine, flying die cut-off techniques are not uncommon. The final section is the exit station, where the finished part exits the machine onto a roller conveyor or table, and is manually moved.